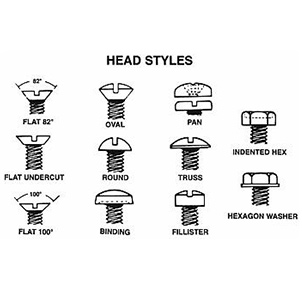

Every screw and bolt has a head that is unique to it’s intended function.

Below is your basic guide to screw head styles and their uses.

At Lianggu Fastener, we supply only the highest quality fasteners. We make it our business to supply you with the durable hardware in the quantities you need.

FLAT 82+

The Flat 82+ head is used for flush surfaces. They are standard countersunk flat head screws.

OVAL UNDERCUT

The ‘oval undercut’ is ideal for shorter screw lengths which require longer thread grip and more shallow countersinking.

PAN

The ‘pan’ head is the most commonly used rounded-top screw head. It works well in a range of applications that require a flat-bottomed screw.

FLAT UNDERCUT

The ‘flat undercut’ is very similar to the standard 82-degree head, having the same angle, but a shorter head. This allows it to provide a longer thread on the same screw length.

ROUND

The ‘round’ head is less commonly used these days, but it offers a round-surfaced alternative to other screw heads.

TRUSS

Truss heads are characterized by a curved surface and an extra-wide top. They are often used to prevent tampering., having a lower profile than most round heads.

FLAT 100+

The Flat 100+ uses a 100-degree angle instead of the standard 82-degree kind. It is an ideal choice for thinner materials that require a flatter head.

BINDING

Often used for electrical applications. The undercut area beneath the head allows space for wire connections.

FILLISTER

The ‘flat fillister’ is identical to a regular fillister screw, except for a flat top replacing the latter’s oval top.

Hex

Common in bolts, hex heads allow for greater torque and are driven with the drivers force against the outside of the head, unlike most drives, which are internally driven.

Hex Washer

Newer and more common version of the hex head. Attached washer style flange under the head creates larger surface connection area. Sometimes available in combination with phillips or slotted drive.